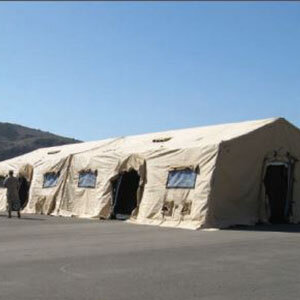

rapid deployment system (RDS)

The RDS is a rapidly deployable shelter system proven to be one of the fastest and most reliable systems on the market today. Made to meet any mission requirement, this patented truss-style frame system is stronger and more durable than standard “scissor” style frames, and can withstand 300 lbs. hanging load at any point on the frame!

When it comes to force protection at remote base operations — worldwide — in any operating environment, the RDS is clearly the most durable, versatile shelter system.

Rapid deployment system Models

RDS 100

Dimensions: 12’6" x 8' x 6’5"

(3.81m x 2.44m x 1.96m)

Useable area: 100 ft² (9.29m²)

Time under cover: 4 min

Complete setup: 4 min

Manpower required: 2 personnel

RDS 320

Dimensions: 20’ x 16’ x 6’11"

(6.10m x 3.05m x 2.11m)

Useable area: 285 ft² (26.48m²)

Time under cover: 8 min

Complete setup: 8 min

Manpower required: 3 personnel

RDS 635

Dimensions: 20’ x 31”9” x 6’11”

(6.10m x 9.68m x 2.11m)

Useable area: 612 ft² (56.86m²)

Time under cover: 12 min

Complete setup: 12 min

Manpower required: 5 personnel

RDS 150

Dimensions: 17’ x 10’ x 6'11"

(5.18m x 3.05m x 2.11m)

Useable area: 145 ft² (13.47m²)

Time under cover: 4 min

Complete setup: 4 min

Manpower required: 2 personnel

RDS 460

Dimensions: 23’6” x 19’9” x 6’11”

(7.16m x 6.02m x 2.11m)

Useable area: 466 ft² (43.29m²)

Time under cover: 10 min

Complete setup: 10 min

Manpower required: 3 personnel

RDS 695

Dimensions: 23’6” x 29’9” x 6’11”

(7.16m x 9.07m x 2.11m)

Useable area: 667 ft² (61.97m²)

Time under cover: 14 min

Complete setup: 14 min

Manpower required: 4 personnel

RDS 250

Dimensions: 17’ x 16’ x 6’11”

(5.18m x 3.05m x 2.11m)

Useable area: 240 ft² (22.30m²)

Time under cover: 4 min

Complete setup: 4 min

Manpower required: 2 personnel

RDS 480

Dimensions: 20’ x 24’ x 6’11”

(6.10m x 7.32m x 2.11m)

Useable area: 458 ft² (42.55m²)

Time under cover: 10 min

Complete setup: 10 min

Manpower required: 4 personnel

RDS 720

Dimensions: 24’6” x 29’9” x 8’11”

(7.47m x 9.07m x 2.72m)

Useable area: 675 ft² (62.71m²)

Time under cover: 18 min

Complete setup: 18 min

Manpower required: 4 personnel

Features and Benefits

Dry, Tough, Fast By Design

The RDS has passed rigorous testing for all MIL-SPEC environmental and durability requirements. Each RDS meets or exceeds all US Military requirements.

The RDS meets the following performance requirements:

Snow Load:

10 lbs. (4.54kg) per square foot (without additional kit).

Wind / Rain:

Sustained winds of 55/65 mph gust (88.51 km/h / 104.61 km/h); 2" (50.8mm) per hour (without wind/guy lines).

Durability:

Completed 82 sets & strikes, well beyond the US Military requirement of 50 (and remained operational for more).

The RDS requires NO SPECIAL KITS for snow, wind or rain load.

Superior Tactical Development

The RDS withstands impact of weighted items stored on top of it, when in its packed state. It has a self-contained frame system, which enables the user to reduce embarkation equipment and storage containers. No structural support is required during transportation, enhancing the speed of operational readiness. In addition, the Eureka! RDS is able to store and stage on tactical vehicles such as the Amtrak, 7 Ton Trucks, Helicopters, Humvees, existing trailers, and many other transport vehicles used by the Armed Forces.

Structural Efficiency

Prior to the RDS, all other fast set up structures relied upon “scissor system” designs. The two key design advantages of the RDS versus scissor systems are:

1. The Creation of a Structural Truss

The advantage of the structural truss is a static load strength to pass 10 pounds per square foot snow loads without additional braces that increase set up time and expense.

2. Fewer Moving Parts of a Structural Truss

The advantage of fewer moving parts/locking pin locations is less failure modes and greater system reliability.

When the RDS is deployed, it forms a structural truss. Each section has a four-sided structure of compressive members with two diagonal tension cables. Upon deployment, the cables are tensioned, becoming the major load bearing element.

Other quick erect tents do not use the structural trusses. Tubes in the scissor system design have pins in each end and at the mid-span — and become the major load bearing element. In addition, the hole at the mid-span is located at the point where the tube has the greatest bending stress during deployment and the greatest opportunity for failure.